Surgical Design Case Study 3 - Dual Material Reconstruction

AT: PDR

FOR: NHS

MY ROLE: COMMERCIAL PROJECT MANAGER / DESIGNER

Clinical Background

The patient had suffered a traumatic injury – resulting in the fracturing and displacement of bones in their orbit, orbital rim, and maxilla. This resulted in a significant facial asymmetry – and functional problems with their eye. The maxillofacial surgeon approached PDR to assist with designing patient-specific implants to correct the aesthetics of the face and the function of the eye. The maxillary defect required posterior gap-filling (back to the original bone) as well as anterior recontouring.

Design

I worked closely with the clinician on this project to plan the surgical procedure digitally, and design patient-specific devices. My carefully structured design process enabled efficient optimisation of the proposed reconstruction whilst ensuring patient safety by anticipating potential problems and constraints. One short online meeting was held to specify the surgical plan, with final device design approval undertaken offline at the surgeon’s convenience.

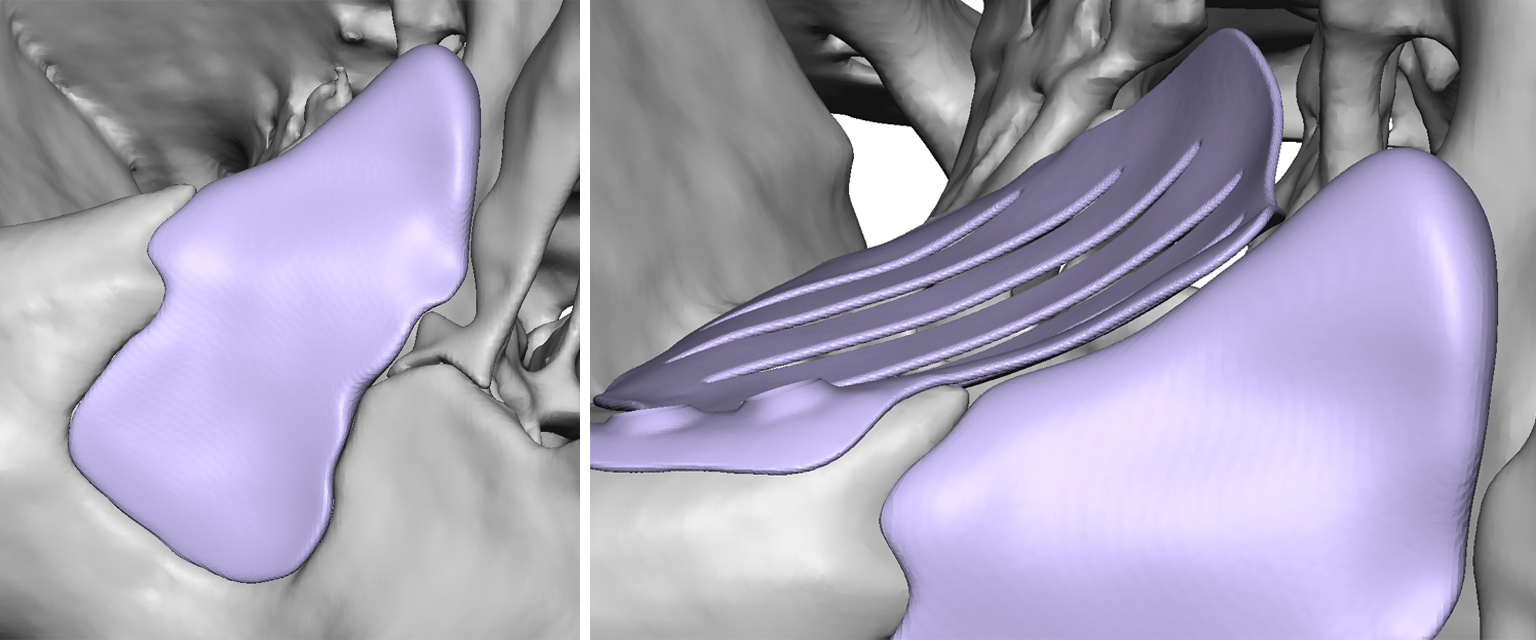

I segmented the patient’s CT scan-data and created a virtual model as the basis for digital surgical planning. The healthy contralateral anatomy, corresponding to the region of interest, was copied and mirrored. Adjustments were made using smoothing and blending techniques to achieve a best-case fit of the mirrored anatomy against the residual injured bone.

I designed a thin titanium implant to restore the location and contours of the displaced orbital floor. Fixation locations were collaboratively agreed and a series of holes added to allow fluid venting between implant sides. I also designed a PEEK implant of varying thickness to restore the contours of the maxilla and fill the space between the impacted bone and the anterior surface. Careful consideration of insertion pathways, undercuts, and the different manufacturing constraints associated with machining was essential. The surgeon chose to fix the PEEK implant using standard mini-plates – with the final positions determined in-theatre.